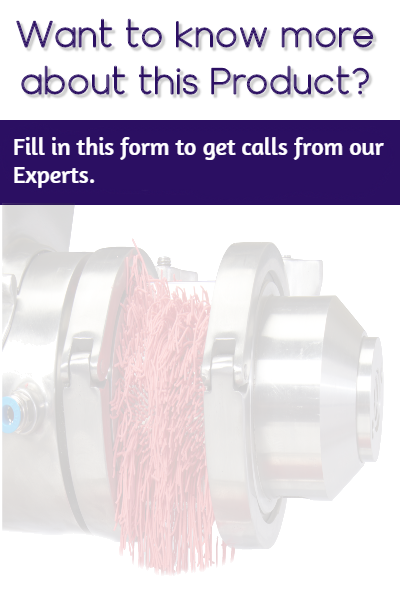

Radial extruder is used for the conversion of dough material and wetted powders in uniform size granules by adding binders. These extruders are immensely used in ceramics, herbals, polymers, catalysts, food, sugar industries and pharmaceutical industries. The radial extruder designed by Umang Pharmatech has features such as long operational life , unmatched quality , integrated unit.

Extruder has either single or twin screws, depending on the output required which transfers the materials to the flat die.

The thickness of the die can be provided as different thickness to deliver a range of compressive energies..Range available from 0.7 to 5 mm with varying thickness up to 5 mm.

Umang manufactures Different models in extruders such as axial extruder, Die Roller extruder, Cone extruder, Basket Extruder, Radial extruder.

Radial screw extruders use semi-cylindrical screens along each side of the counter rotating screws, combined with, more or less, conical extrusion heads. Typical for the radial extruders is that they have "overflow", which means that a certain amount of product passes the extrusion area without being pushed through the screens. This overflow material leaves the machine at the front end. Compared to other extruder technologies, these radial extruders produce granules with a medium density and medium hardness.

Technical Specifications for Radial Extruder:

| Model | USSE - 60 | UTSE - 70 | UTSE - 110 | UTSE - 140 |

| Batch Cap./Kgs. | 1-10 kgs / hr | 20-60 kgs/hr | 80-150 kgs/hr | 200-400 kgs/hr |

The Umang Pharmaceutech Test Station is located in Vasai, THane, conveniently located very close to Mumbai airport, only forty five minutes from Mumbai International Airport. The Test Station's purpose is to assist our Pharmaceutical and Biopharmaceutical Industry customers with feasibility testing of their products on our equipment, and to be a partner with them in the process development as they move forward from the Research and Development stages to clinical production, and eventually into full-scale Manufacturing.

The station combines decades of design and development know-how in the pharmaceutical industry with the very latest in processing equipment to provide you with a unique opportunity for feasibility, development, and small-scale manufacturing of pharmaceutical products.

Your needs are critical and individual. The UMANG Pharmaceutical Test Station has been designed to meet those needs.

Our expertise in formulation development extends to the development of all conventional dosage forms. Our strategic alliances broaden the scope to consider many Novel Drug Delivery Systems (NDDS), including transdermal & liposomal delivery systems. We consider multiple approaches to improve the bioavailability of drugs. We have expertise in improving delivery of poorly soluble/ permeable drugs and the capability to screen potentially innovative drugs based on pharmacokinetic properties. We possess pelletization, drug-layering, particle-coating and other technologies to achieve extended release profiles for tablets or capsules.

Our analytical development services include assay and RS method development and validation, dissolution method development and validation, stability studies as per ICH guidelines, polymorphic form characterization (DSC/TGA/XRD/Microscopy), cleaning validation studies and HPLC to UPLC method conversions.

Can we make micro pellets ?

Yes, with Radial Extrusion.

What type of material is suitable to process in a radial extruder ?

Non-sticky , powdered

What are the particle size constraints ?

There are no constraints we design the machine as per your product requirements .

Will the process heat up my material excessively ?

No there is a uniform air distribution in the machine.

How often should I clean the machine ? Are the parts easily available ?

Yes the parts are easily accessible for product change over.

Do you offer the machine in mild steel construction for industrial application ?

Yes we do offer the same for procie sensitive products / segments .

How quick can we get the delivery ?

3-4 weeks depending on the size.

Do you provide a complete processing line ?

Yes we do give machine from high shear mixing to extrusion , spheronization to fluid bed drying/coating as per product / process needs.

Is the Extruder and powder feeder controlled by a inverter?

Yes.